We have called this area of our website the ‘quality toolkit’ as we believe it provides a good analogy for anyone working in construction — the idea of using ‘tools’ to achieve something.

We aim to provide explanations, from a construction perspective, for some of the tools that might be used to help with quality management.

Single tools

Some of the tools we use are single items and have a very specific purpose, such as a pipe cutter used to cut pipes when doing plumbing work. Quality tools such as ‘5 whys’ or ‘fishbone diagrams’ could be considered ‘quality tools’ which have a single specific purpose.

Pipecutter: A tool with a single purpose

Types of tools

‘Screwdriver’ or ‘hammer’ are generic names but there are different types, eg: slot, pozi drive, Phillips etc or claw, club etc, and the specific type of tool used will depend on the task.

Different types of a tool (e.g. ‘hammer’ or ‘screwdriver’)

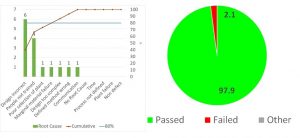

Similarly, quality management tools such as graphs will vary depending upon the requirement. For example, Pareto charts may be used to indicate the top reasons for defects occurring whereas pie charts can be used to show proportions.

Graphs as a quality management tool (e.g. Pareto chart and pie chart)

Multi-purpose tools

Other tools such as electric drills have several different attachments for different functions. Quality management tools such as ‘lean’ and ‘six sigma’ provide multi-purpose techniques that organisations can use to bring about improvement. In fact, organisations may employ full time specialists (eg lean consultants, six sigma black belts) dedicated to championing these initiatives.

Electric drill: A multi-purpose tool

Seven basic quality tools

There are seven basic quality tools for improvement:

- Cause & effect diagram

- Check sheet

- Control charts

- Histogram

- Pareto charts

- Scatter diagram

- Stratification

Although there are many other tools, we suggest the top six basic tools for construction might be:

- Inspection and test plans

- Checklists

- Lean

- 5 Whys

- Fishbone diagrams

- Pareto charts

Caution: ‘checksheets’ are often confused with ‘checklists’ and the terms used interchangeably. However, checklists and checksheets are actually different quality management tools:

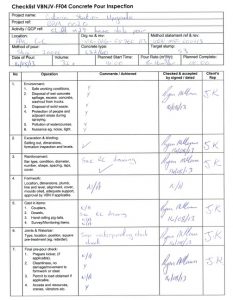

- A checklist is a list of activities or checks which must be completed (often in numerical order). The checklists used by airline pilots are a typical example. A checklist acts as an aide memoire as well as providing verification that the activity has been completed (eg by a tick or signature). Here is an example of a checklist:

Example of a checklist (for concrete works)

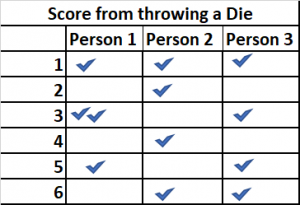

- Checksheets are used to help collect data. A checksheet would be used to record the number of times something happens. Here is an example of a checksheet:

Example of a checksheet

Further reading

The idea of representing the above techniques used for quality management as ‘tools’ is not new and ‘The Quality Toolbox’ by Nancy R Tague provides further explanation:

https://asq.org/quality-press/display-item?item=H1224

Read an extract at: http://www.orion2020.org/archivo/calidad/1a/calidad_toolbox.pdf